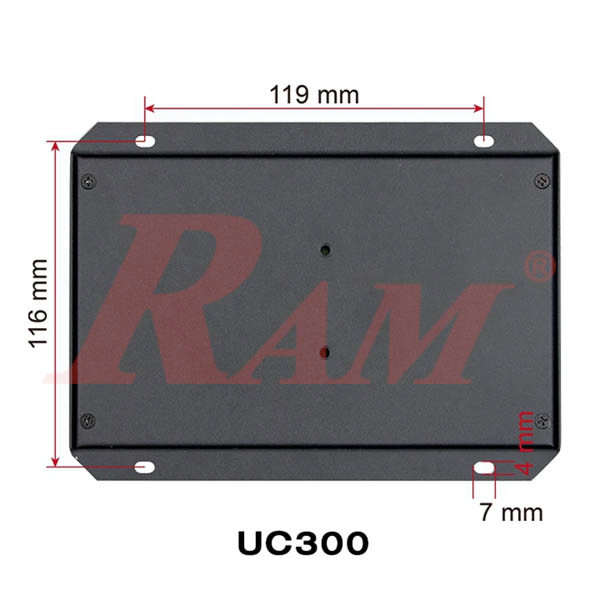

UC300 MACH3 USB 6-Axis CNC Controller

مرجع داخلي:

KIT.UC300.6.AXIS

UC300 Mach3 USB 6-Axis CNC Motion Controller – Product Data

Overview

The UC300 6-Axis is a high-performance external motion controller designed for Mach3 CNC software. Unlike standard 4-axis models, this version supports up to 6 axes (X, Y, Z, A, B, C), making it ideal for advanced CNC machines requiring multi-axis synchronization. It communicates via USB, removing the need for a parallel port and delivering smooth, precise, and stable motion control for both stepper and servo systems.

Key Features

- Axis Support: Controls 3 to 6 axes (X, Y, Z, A, B, C)

- Pulse Output: Up to 300 kHz per axis for high-precision motion

- USB Communication: Stable, real-time communication with Mach3 via USB

- Motor Compatibility: Works with stepper and servo motors using pulse/direction signals

- Digital Inputs: 16 opto-isolated digital input ports (varies slightly by PCB revision; most 6-axis models provide more inputs than the 4-axis version)

- Digital Outputs: 12 opto-isolated digital output ports for relays, coolant, spindle control, etc.

- Analog Output: One 0–10V analog output for VFD spindle speed control (PWM configurable)

- Power Supply: Operates on 24V DC, minimum recommended current 1A

- Motion Control Chip: ARM-based motion controller ensures stable and reliable performance

- MPG Support: Compatible with standard MPG handwheels and DigitalDream MPGs

- Extended I/O: Additional pins made possible due to expanded 6-axis architecture

Technical Specifications

- Maximum Pulse Frequency: 300 kHz per axis

- Supported Axes: X, Y, Z, A, B, C (6-axis)

- Input Voltage: 24V DC (≥1A)

- Digital Inputs: 16 opto-isolated

- Digital Outputs: 12 opto-isolated

- Analog Output: 0–10V (PWM optional)

- Communication Interface: USB

- Supported Software: Mach3

- Supported Motors: Stepper and servo motors using pulse/direction interface

- MPG Interface: Supported

Applications

- 6-Axis CNC milling machines

- CNC routers with rotary or tilting axes

- CNC plasma cutters

- 5-axis or 6-axis engraving machines

- Robotic arms and multi-axis motion platforms

- Any CNC system requiring precise multi-axis synchronization

Note

Proper configuration in Mach3 is required to ensure stable 6-axis operation. Verify wiring, power supply specifications, and input/output mapping according to the manufacturer’s documentation.

Your Dynamic Snippet will be displayed here...

This message is displayed because youy did not provide both a filter and a template to use.